Claas: precision farming at the cutting edge

At the 'Greenhouse' innovation centre – the place where Claas tests new products with customers – Wolf-Christian von Wendorff, responsible for Global Digital Solutions, explains how sensor technology, data and autonomy are protecting fields and driving yields.

Wolf, Claas has been producing harvesting technology for generations now. What exactly does the company stand for in 2025?

Claas stands for integrated precision agriculture. We do not just build machines; we provide the systems and the controls behind them. Digitisation started for us back in 1972 – more than 50 years ago; our customers have been pioneers in digitisation for years. I am thinking here of precision farming or milking robots, long before their widespread use in industry. With “Claas connect” we can now connect the entire fleet of agricultural machinery, from combine harvesters and forage harvesters to tractors and implements. It allows farms to work with centimetre accuracy, conserve resources and secure yields.

In the past, an entire farmed field was treated uniformly; today it is monitored with centimetre precision via satellite.

What does precision agriculture achieve in the field?

In the past, an entire farmed field was treated uniformly; today it is monitored with centimetre precision via satellite. This reduces overlaps in fieldwork, for example when sowing, spraying or fertilising. Our machines can maintain a track in the field with an accuracy of up to 1.5 centimetres. This saves seeds, water and other resources – and gives each plant the space it needs.

So how do farmers decide where to fertilise and where not to?

We create so-called application maps that combine data from several sources: satellite images and drone data for vegetation development, previous year's yields, soil maps, elevation profiles. These maps allow farmers to identify where fertilising makes sense and where it does not. An example: less grows on a hill. Often there is a lack of water, not nitrogen, and that means: less fertilising. The maps are digitally transferred from Claas connect to the machine terminals and water, fertilisers, sprays or seeds are deployed as needed.

Autonomous machines in the field – how is that organised?

This must, of course, be well planned and prepared. Am I fertilising, sowing or harvesting? How do I set up the machine correctly? Which field do I want to work and when? The machine recognises obstacles, navigates around them, makes decisions and provides observational data. This creates a cycle of deployment, evaluation and improvement that leads to fully autonomous fieldwork.

What else can your machines do?

Our electronic machine optimisation system “CEMOS Automatic” adapts to the precise conditions of any field while driving across it. This makes driving much easier for the driver and reduces errors. Fieldwork becomes more efficient, more sustainable and, above all, saves resources.

The next step is autonomy: where machines work alone, their actions based on extensive and diverse data, monitored remotely and connected to the farm and other machines.

We only have one world and it has to feed us all.

Let’s talk about AI: is it just a buzzword in your view, or does it actually create added value?

I said before: digitisation in farming is already incredibly advanced. AI is the next big thing for us. It can process huge amounts of data: weather, soil, field history, satellite images, experience, market and cultivation forecasts, to name important examples.

This enables us to support our customers in making even better decisions about what is good for the respective field.

Currently, the size of an area that we can precisely determine how to cultivate is getting smaller and smaller. Soon sensors will be able to identify exactly what each single plant needs: fertiliser, crop protection or maybe no intervention at all.

Weeds can be removed either mechanically or with lasers. This requires extremely precise work – sometimes also very slow work, which is hardly feasible without autonomy. AI makes situational decisions; the machine implements them.

With a view to climate change and resource scarcity, how can technology help?

We only have one world and it has to feed us all. So we need to be as careful with our resources as we can. Our technology can help us do just that, allowing farmers to increase yields, use less water, less fertiliser, less spray and less fuel.

Another example is our TERRA TRAC system that distributes the machine's weight over a larger area, protecting the soil. With predictive maintenance, we can reduce downtime, and if something does get stuck, remote diagnostics help.

In short: more hectares per day, less input per hectare, better yield per operation.

Technology is one thing, people are another. How do you work with farmers?

We are a family business and close to the farmers, not least because many of our colleagues in our workforce are farmers themselves. Our 3,500 dealerships also mean we are very close to our customers. During harvest, the machines are in operation around the clock. A combine harvester, depending on equipment and size, requires a high six-figure investment and on average only works eight weeks a year – every hour of downtime is expensive.

Our service partners ensure that the machine – should it break down – is quickly ready for use again. For this, our technicians can, at the customer's request, connect to the machine and identify the problem. If it cannot be solved remotely, the technician ideally has the right parts with him on his first visit. Claas connect digitally connects customers, dealers and manufacturers – including feedback loops. This ensures that customer feedback always reaches us immediately and that we can make our machines or digital solutions even better.

A combine harvester, depending on equipment and size, requires a high six-figure investment and on average only works eight weeks a year.

Who owns the data, who can see it – and who cannot?

Europe has one of the best data protection legislations worldwide, which perfectly fits our self-image. The data belongs exclusively to the customer. Access is only granted with consent and for clearly defined purposes – this is controlled via Claas connect: The customer can grant, limit or revoke access rights, as well as export or delete their own data. Without customer approval, there is no access.

Does Claas go beyond classic agricultural technology? Are vertical farming, food tech or start-ups topics of interest for you?

These are all exciting areas of innovation, but our focus remains on producing food using natural resources like soil, water and sun light. Vertical farming can serve a niche demand but it will never sustain global food supply. When it comes to start-ups, we are working with AgXeed to jointly develop autonomous agricultural machinery. We welcome collaborations like this and are, in fact, actively looking for them through our Seedgreeninnovations programme. Collaborations help us support our core business.

Finally, a look ahead: how do you see agriculture in 2035?

Three forces will shape the future of farming: robotics, autonomy and AI. Robotics brings precision to tools, autonomy takes over routine tasks, AI supports management decisions – both at the planning stage and during operation. From the office to the field. Ultimately, what counts is experience in the form of data. The farmers with the most hours out on the field and who can collect as many sets of clean data as possible today will be among the best in 2035.

Combine harvester - size comparison

This interview was published in October 2025.

Claas and Deutsche Bank: a global partnership

Claas Group and Deutsche Bank share a long-standing business relationship since the 1950s spanning from Europe to Asia. Deutsche Bank plays a key role in financing for Claas. At the heart of the partnership is the bank’s participation in a revolving syndicated credit facility that provides Claas with flexibility and stability. Deutsche Bank also supports Claas with cash management, capital market transactions and FX management – crucial for efficient payment flows, currency risk mitigation and access to international markets.

About Wolf von Wendorff

Wolf von Wendorff is Senior Vice President for Digital Solutions at Claas Global Sales GmbH. He has a BSc in Agriculture and an MBA.

His strengths lie in the strategic development of sales and service organisations, the establishment of agile IT structures and the implementation of complex IT portfolios. He is responsible for the development of digital sales and service solutions for retailers as well as for digital customer products that make it easier for retailers and customers to work together, benefit from better service experiences and analyse their data in a targeted manner.

About Claas

Founded in 1913, Claas is a family-owned company and one of the world’s leading manufacturers of agricultural machinery. With its headquarters in Harsewinkel, North-Rhine Westphalia, Germany, Claas is the world market leader in self-propelled forage harvesters and the European market leader in combine harvesters. Claas is also one of the world’s leading manufacturers of agricultural engineering equipment with tractors, agricultural balers and green crop harvesting machines. The Claas product portfolio also includes state-of-the-art farming information technology. Claas employs almost 12,000 people worldwide and generated 5 billion euros in sales in 2024.

Timo Bergold

... is usually engaged in global communications projects and supports financial communications within the international environment of Deutsche Bank. For the interview at Claas, however, he changed perspective and immersed himself in the world of digital agriculture. Experiencing innovation and practical application up close was an inspiring experience for him.

Recommended content

Entrepreneurial Success | Video & Photo Story

Acesur: When Innovation is your DNA Acesur: When innovation is your DNA

Artificial intelligence, data-based decisions, biodegradable packaging: How a traditional Spanish family business is revolutionising the olive oil business.

Entrepreneurial Success | Story

Grows even in the desert Grows even in the desert

Veganz founder Jan Bredack is on a mission to feed the world by producing plant-based protein on an industrial scale.

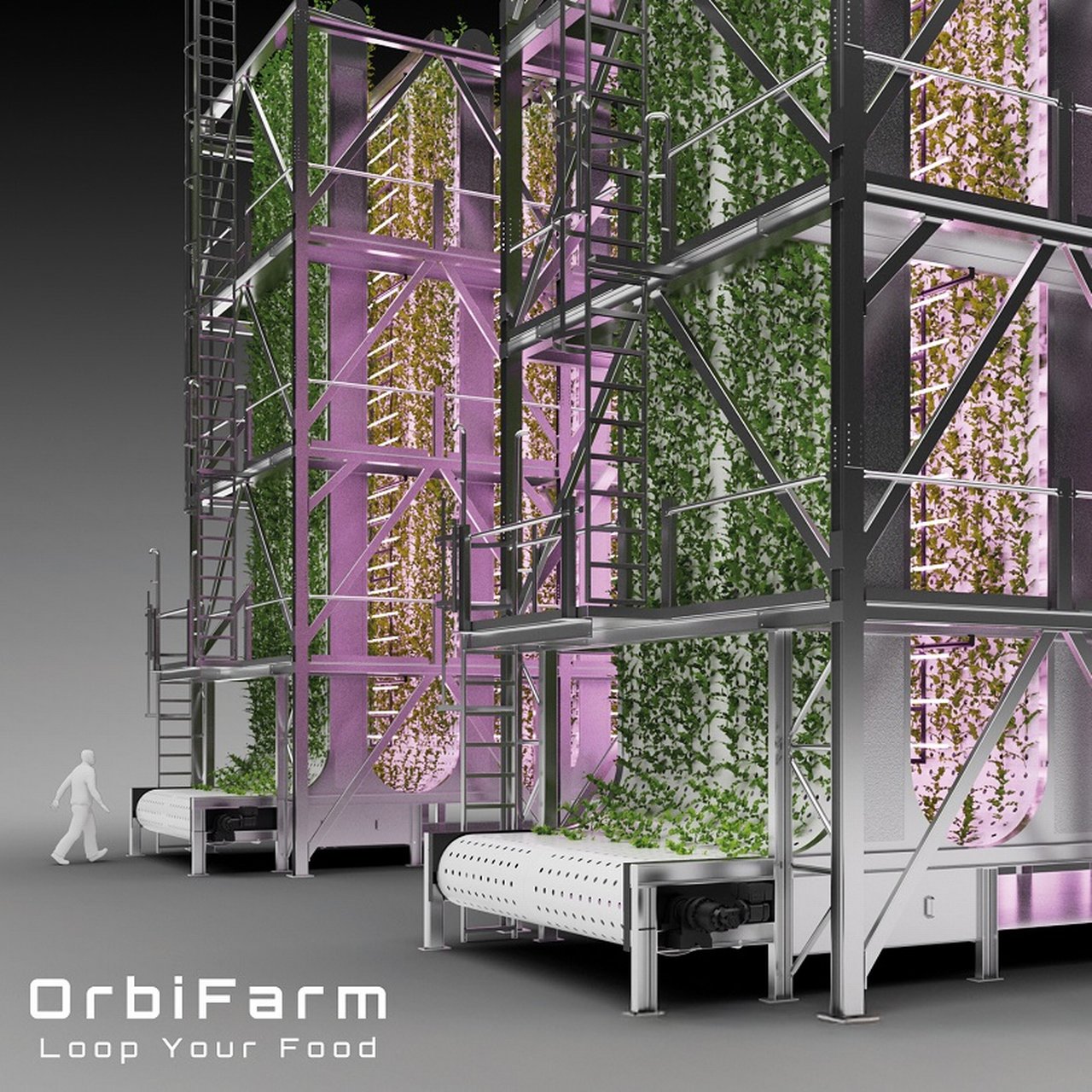

This vision will become reality with OrbiFarm®. Here’s how.

Entrepreneurial Success | Photo Story

Leading the way with regenerative agriculture Leading the way with regenerative agriculture

Instead of waiting to see how climate change and species extinction affect its own production, the medium-sized company Schwartauer Werke started early to produce more sustainably.