The pinnacle of green construction: the best from nature and the lab

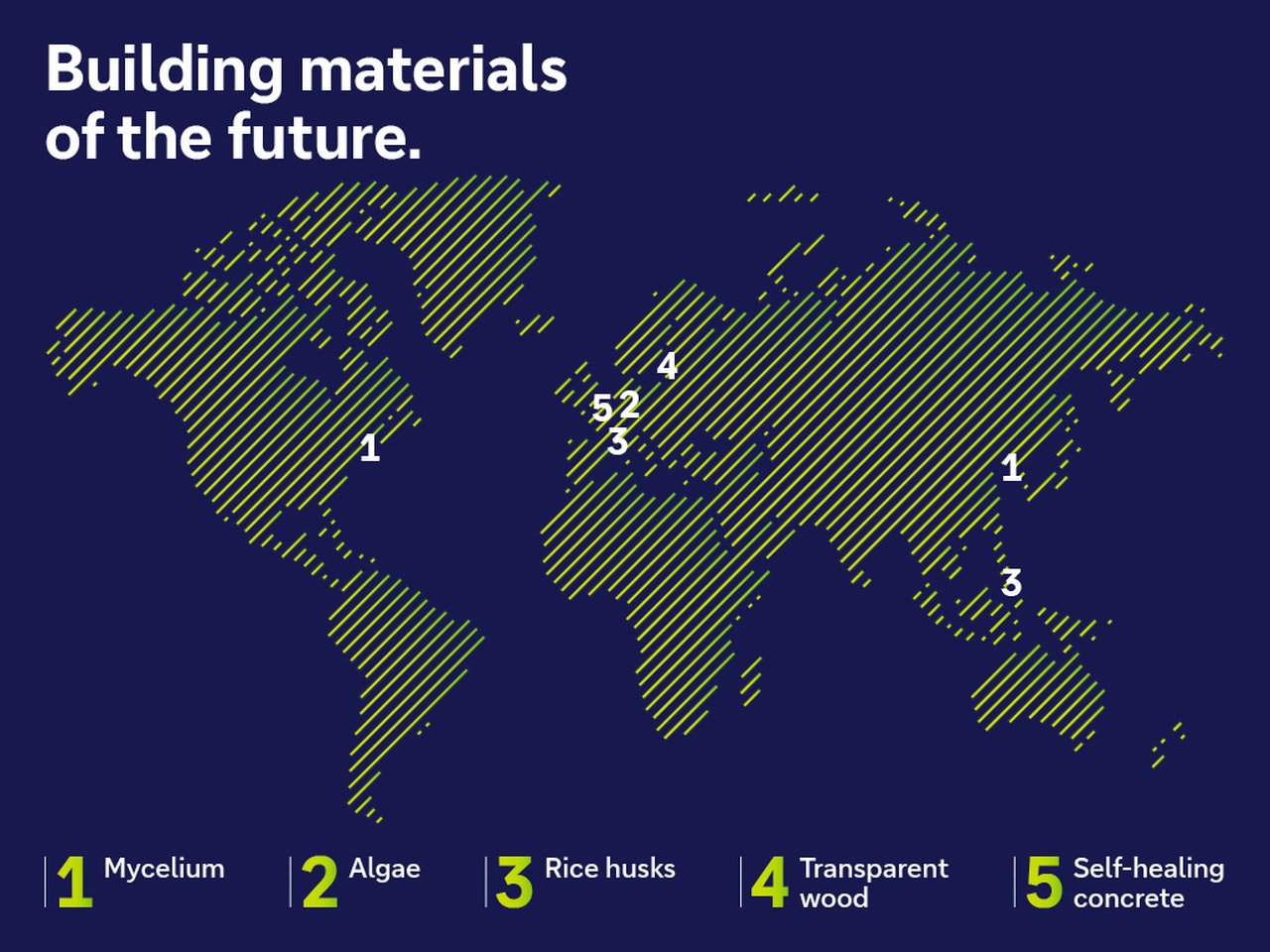

Eco-friendly construction has many approaches but the most exciting development is the materials themselves. Instead of concrete and steel, fungi or algae are taking centre stage. What sounds like science fiction is already being researched, tested and built.

Inspired by Hy-Fi, the world’s first mushroom tower

From the depths of the earth up to the sky: mycelium

Mycelium is the underground root network of fungi – a network of fine threads that grows on organic waste. Under controlled conditions, it can grow into almost any shape, inspiring environmental pioneers, architects and designers alike.

Mycelium also scores with other properties important for the construction industry: Thanks to its dense cell structure and high water content in its initial state, it is flame-retardant and even outperforms many synthetic materials in terms of sound insulation.

The transience of the building material is both an advantage and a disadvantage. Mycelium is completely compostable without harmful substances. However, biodegradable also means, without protection, its lifespan is limited.

The "Hy-Fi" project shows what is fundamentally possible. In 2014, New York architect David Benjamin was invited to submit a design for a MoMA exhibition. He was fascinated by fungal technology and wanted to use it for a tower. Together with Ecovative, a pioneer in the use of mycelium as a natural adhesive in packaging material, and the laboratories of Columbia University, he grew the mycelium with straw into bricks. Benjamin won the ideas competition and built a 13-metre-high tower for MoMA, the first mushroom tower in the world. The so-called "Hy-Fi" was dismantled after three months and composted without residue.

Research continues on water resistance and load-bearing capacity, for example at the Karlsruhe Institute of Technology and ETH Zurich. In 2017, the joint project "Myco Tree" created the world's first load-bearing structure made of fungal mycelium, which was presented at the Seoul Biennale of Architecture and Urbanism. The team impressively demonstrated that, through a statically optimised form, even materials of relatively low strength can still bear load and create space – an important basis for the future use of mycelium as a building material.

A glimpse through green: algae facade on the BIQ House in Hamburg. Credit: IBA Hamburg GmbH / Johannes Alt

All-round algae

Algae offer a wide range of applications in construction. For example, they serve as a raw material for biodegradable plastics and insulation materials. Microalgae such as spirulina or chlorella can produce limestone through biomineralisation, which serves as a basis for CO₂-reduced cement. Algal oils can be converted into carbon fibres: lighter than steel, but similarly strong, they are ideal for load-bearing structures, bridges or facade elements.

Algae-based facade materials also offer exciting approaches. In algae biofilm facades, thin layers of microalgae grow on a prepared substrate, such as porous concrete. The biofilms clean the air and thus improve the microclimate. So-called photobioreactor facades house and cultivate microalgae in transparent glass elements. Here, the algae carry out photosynthesis, grow, bind CO₂ and produce biomass that can be used for energy. Disadvantages? Algae growth is weather-dependent, is expensive and labour intensive.

But it works! The "Bio Intelligent Quotient House" (B.I.Q.) in Hamburg-Wilhelmsburg, realised in 2013, was the world's first building with a bioreactive algae facade. It is considered groundbreaking because it combines architecture, biotechnology and energy efficiency. In addition to sun protection and thermal energy generation, the house also has something to offer visually: depending on the type of algae, lighting conditions, and growth phase, the colour of the facade can change dynamically – from green to brown to reddish hues. This makes it a vibrant design element.

What’s more, unlike classic facade greening, algae facades do not need any connection with the ground so they can be installed on narrow, sealed surfaces – ideal for dense inner cities.

What will the future bring? Research continues, for example, on the live algae facade at RWTH Aachen University. The focus here is on improving the thermal insulation and energy efficiency of buildings. But tinkering is also taking place elsewhere, and to ensure that all researchers know and can learn from each other, the European Commission is recording all EU-funded algae projects in the “EU4 Algae Project Database”.

A brilliant idea for waste: buildings encased with leftovers from rice production. Credit: Ricehouse

From waste to resource: rice husks

Rice husks are a by-product of rice processing that has mostly been considered waste. When combined with binders such as bio-based resins and additives such as rock salt or recycled plastics, a mixture is created that can be pressed into panels or profiles. These so-called rice husk boards can replace wood or plastic in construction.

The list of advantages is long: rice husks are extremely resistant. They contain up to 20 percent quartz and are therefore waterproof, weather-resistant and fire-retardant, and are considered UV- and pest-resistant – all without additives. Rice husk panels are thermoplastic, meaning they can be moulded with heat, and they also provide thermal insulation. Because they can be processed like wood, fewer trees would need to be felled if rice residues became a common building material. Too good to be true? Only time will tell, as long-term studies on durability and ageing are still lacking.

After the devastating earthquake on the Philippine island of Bohol in October 2013, which left over 350,000 people homeless and damaged around 80,000 houses, the "Husk-to-Home" project was created, focusing on the development and use of rice husk panels. The US Environmental Protection Agency (EPA) supported the project as part of its P3 programme ("People, Prosperity and the Planet"), which promotes student initiatives for sustainable development. This funding enabled the team from the University of California – Riverside to advance materials research and, together with local partners, build the first houses on Bohol using the new panels.

The potential of rice husks is also being recognised in Europe. In 2016, architect Tiziana Monterisi and Alessio Colombo founded the start-up Ricehouse in Biella (Piedmont, Italy). The company specialises in the use of rice husks and other by-products of rice processing. Today, Ricehouse offers a wide range of building products, including insulation panels, plaster and facade systems.

Peephole into the future: transparent wood combines natural aesthetics with smart functions. Credit: timber-online.net

Age-old material newly defined: transparent wood

Transparent wood is an innovative material made from natural wood that is treated to become translucent. How does this work?

Spruce, birch or balsa wood have a low density and a uniform structure. This makes them particularly suitable. First, the wood is cut into thin layers and then immersed in hydrogen peroxide. Other liquids that extract lignin from the wood are also suitable. It is the lignin that makes the wood opaque.

What remains is a whitish, porous wood framework made of cellulose, which in the next step is impregnated with a transparent polymer, for example, epoxy resin. Through heat or UV light, the material solidifies into a translucent material with astonishing properties.

Transparent wood is more shatterproof and lighter than glass, making it ideal for earthquake-resistant buildings or load-bearing structures. The light scattering ensures natural, glare-free lighting – with a light transmission of up to 85 percent. It also has better insulating properties than glass, which makes it particularly attractive for energy-efficient buildings. The structure of the wood is retained, thus combining mechanical stability with natural aesthetics.

The breakthrough in the research of transparent wood was achieved in 2016 at the KTH Royal Institute of Technology in Stockholm. Since then, teams have been working on pilot projects and prototypes worldwide. In the future, transparent wood could even be a carrier material for solar cells – and thus transform windows into power sources. There are also initial approaches for smart technologies in which the material is combined with temperature control or light control

However, challenges remain. The removal of lignin requires chemical processes that are energy-intensive and not always environmentally friendly. Recycling is also difficult because the combination of natural wood and synthetic polymers makes it difficult to separate the materials and recycle them.

Bacteria make it possible: concrete learns to repair itself. Credit: College of Engineering and Applied Science at Colorado University Boulder

Self-healing concrete: the future of construction is starting to grow

Concrete is strong, versatile and an integral part of our world – but when it cracks, it becomes expensive and time-consuming to repair. What if concrete were clever enough to repair itself – without the need for manual labour or construction sites?

Self-healing concrete makes this possible. To trigger the self-healing process when needed, additives are mixed into conventional concrete during production. These can be bacteria that produce limestone when water penetrates, thereby sealing cracks up to a maximum of 0.5 millimetres (biologically self-healing concrete).

Another option is microcapsules filled with, for example, epoxy resin or silicates. When cracks form, the capsules burst open, the substance fills the cavities and hardens (capsule-based approach). In mineral self-healing concrete, additives such as crystallisation agents are introduced, which react on contact with water, form new crystals and thus close cracks in the structure.

Even if the additives and the complex production increase manufacturing costs by up to 50 percent, the advantages of self-healing concrete are obvious: tunnels, bridges, dams, underground car parks, multi-storey car parks and other structures can be maintained over a longer period and at lower cost. They "live" longer and offer us greater safety.

The fact that bacteria are patient and can wait in a dormant state for up to 200 years for their deployment contributes to this, as does the ability of some concretes to heal multiple times.

Pilot and research projects already exist. The Technical University of Delft in the Netherlands built a mobile pedestrian bridge in 2015 to showcase this novel concrete and test the bacteria technology. Also in the Netherlands, in Apeldoorn, a multi-storey car park made of bacteria-based concrete was completed in 2017. It was one of the first larger practical projects to be realised with the concrete developed by TU Delft. Throughout Europe, there are listed buildings where microbial mortar is being tested. The names of specific buildings are not publicly known, but the Parthenon in Athens is frequently mentioned in research.

And what's next? Concrete should not only be able to heal itself, but also become intelligent. Researchers are working on adding sensors or smart materials to it that can monitor and report on the current condition of a structure – for more safety and fewer construction sites.

Building without concrete: bye-bye grey, hello yay!

While conventional concrete and steel still dominate construction sites around the world, the materials mentioned above and other exciting building materials are waiting in the wings. Ferrock, which absorbs CO₂ instead of emitting it, bamboo, which grows faster than you can say “cement mixer”, and hempcrete, which is not only sustainable, but also surprisingly stylish.

We’re at a turning point. The building materials of the future aren’t just green, they’re clever, lively, sometimes even self-healing – and they challenge our imagination. Building will be different. The cracks in the system are visible – and this time, that’s good news.

Mycelium root network of fungi can grow into any shape Mycelium

Mycelium is the underground root network of fungi – a network of fine threads that grows on organic waste. Under controlled conditions, it can grow into almost any shape, inspiring environmental pioneers, architects and designers alike.

Algae can produce limestone through biomineralisation Algae

Microalgae such as spirulina or chlorella can produce limestone through biomineralisation, which serves as a basis for CO₂-reduced cement. Algal oils can be converted into carbon fibres: lighter than steel, but similarly strong

Rice husks can replace wood or plastic in contruction Rice husks

When combined with binders such as bio-based resins and additives such as rock salt or recycled plastics, a mixture is created that can be pressed into panels or profiles. These so-called rice husk boards can replace wood or plastic in construction.

Opaque wood Transparent wood

First, the wood is cut into thin layers and then immersed in hydrogen peroxide. What remains is a whitish, porous wood framework made of cellulose, which in the next step is impregnated with a transparent polymer. Through heat or UV light, the material solidifies into a translucent material.

Selfhealing concrete bacteria help concrete to repair itself Self-healing concrete

To trigger the self-healing process when needed, additives are mixed into conventional concrete during production. These can be bacteria that produce limestone when water penetrates, thereby sealing cracks up to a maximum of 0.5 millimetres.

This page was published in November 2025.

Antje Schmaus

… is always looking for exciting facts and formats to inspire colleagues around the world. For her, "living in harmony with nature" is not just a feel-good factor, but the basis for the future of sustainable construction.

Recommended content

Responsible Growth | Opinion

“The elephant in the climate room” “The elephant in the climate room”

Philipp Misselwitz has a vision: the construction sector can protect the planet rather than harm it. In an interview, he shares how this might work.

“The elephant in the climate room” Unlock expert insightsResponsible Growth | Quiz

Quiz: Still building or already amazed? Quiz: Still building or already amazed?

How future-proof is your knowledge about building for tomorrow? Test your know-how on the most exciting materials and find out if you’re already thinking ahead of the crowd.

Quiz: Still building or already amazed? Curious minds click hereResponsible Growth | Crisp & Short

Beyond beauty: buildings that work for the planet Beyond beauty: buildings that work for the planet

From power-generating lifts in Frankfurt to an unexpected oasis in London – discover how the bank is helping shape the future of building and working.

Beyond beauty: buildings that work for the planet More than just a facade